A back pressure valve is a type of control valve that holds pressure on production vessels such as separators, treaters, and free water knockouts and releases upstream pressure when a designated set point is reached.

what does back pressure mean?

Simply put, back pressure is pressure that is held back. “Back” in this context means against the natural flow of fluid or gas.

In oil and gas applications it refers to upstream pressure that is held, or maintained, in a variety of production vessels to provide the right conditions for separation and processing.

Invention of the Back Pressure Valve

The Kimray Back Pressure Valve was our original valve, and it remains our most popular. Kimray founder Garman O. Kimmell created this product in 1948.

Up to that point, oil and gas producers had to supervise their wells and adjust back pressure by hand to keep production running. Garman’s new invention isolated the operation of the valve from the sensing point of the pressure upstream or downstream.

This meant producers could more accurately control their pressure across a variety of flows using the regulator.

How Do Back Pressure Valves Work?

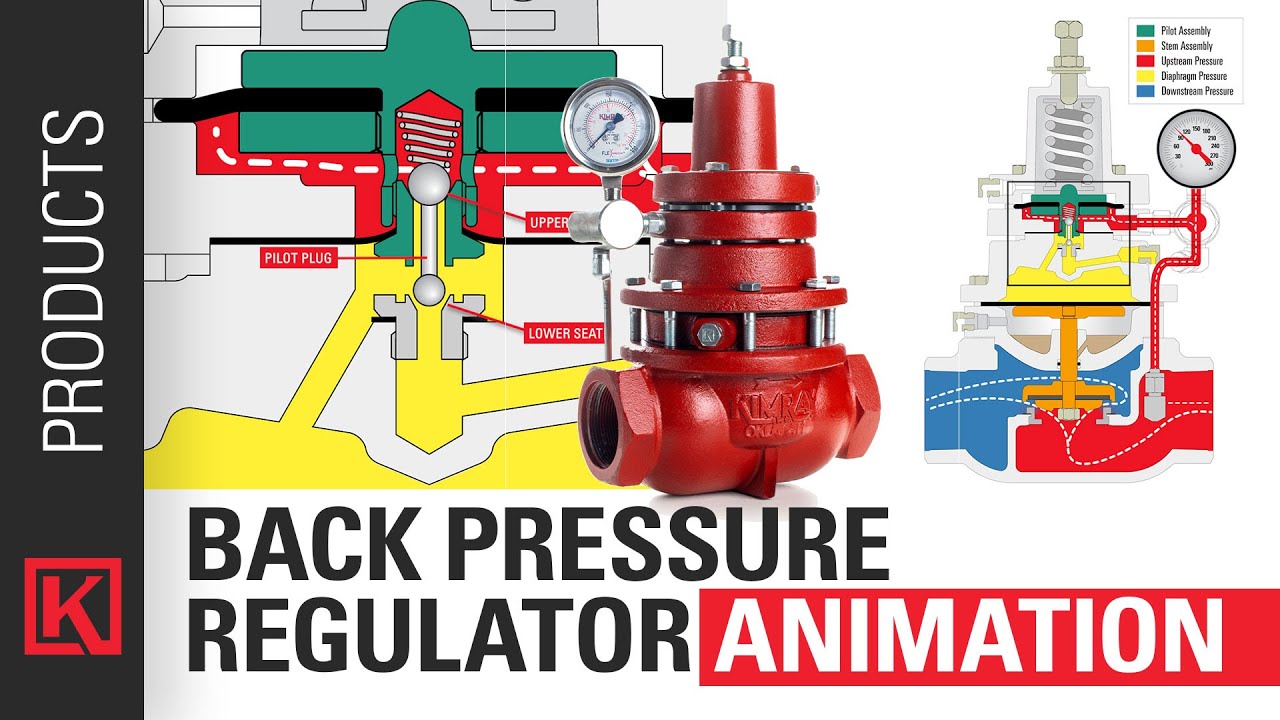

The Back Pressure Valve is an “integrated” valve because the pilot—the key to opening and closing the valve—is connected to the valve and comes out as one piece.

The valve monitors upstream pressure. To adjust the set point, turn the adjustment bolt on top.

The spring pushes down on the diaphragm assembly, which positions the pilot plug. The pilot plug then allows gas from upstream to push down on the diaphragm.

Watch: Video Animation of a Back Pressure Valve at Work

The flow through this valve is from underneath the plunger. The flow pushes up on the plunger as the gas is pushing down on the diaphragm.

Because the diaphragm has a larger surface area than the plunger, the same pressure can hold the valve in a closed position.

This sets a constant back pressure and the valve will begin regulating the pressure.

If pressure exceeds the set point, the upstream pressure pushes up on the diaphragm assembly, closing off the pilot plug. Gas then vents from the top of the diaphragm and the valve regulates the upstream pressure.

What Options are Available?

Back Pressure regulators come in a variety of options to meet your particular flow conditions. Options include:

- 1 inch through 6 inch

- non-vent for zero-emission operation

- outside supply for zero-emission operation (with air compressor)

- elastomer options

- stainless steel valve trim

Applications for the Back Pressure Valve

Examples of vessels that require back pressure include separators, heater treaters, free water knockouts, dehydration units and compressors.

In order to perform their function appropriately, these vessels must maintain a constant pressure. This allows fluid or gas to process through the vessel and out for sale, further processing, or disposal.

If this pressure were not consistent, the separation and processing of oil, gas, and water would prove much more difficult.

How to Troubleshoot a Back Pressure Valve

Here are four things to check if your Back Pressure Regulator is not operating correctly:

1. Remove the Stopper from the Breather Plug

If your Back Pressure Regulator is stuck in the ON position, the small red stopper may still be in the breather plug.

We put this stopper in the breather plug so oil doesn’t spill out during transportation. This can be removed by hand to ensure your breather plug doesn’t get air locked.

2. Check for Wet or Dirty Gas

If your Back Pressure Regulator is venting continuously, the likely cause is you have wet or dirty gas in your pipeline. To fix, you want to remove the bonnet and pilot housing to access the pilot plug. To correct, remove, clean, and dry the pilot plug, then re-install it.

Back Pressure Regulators are meant for gas only, so if this continues to be a problem, you may consider bringing in dry supply gas to your regulator.

3. Tighten the Pilot Plug Seat

If your regulator will not open, a likely cause is that the pilot plug seat is loose. To address this, remove the bonnet and the pilot plug housing to access the pilot plug seat. With a wrench, make sure the pilot plug seat is snug.

4. Tighten (But Don’t Over-Tighten) the Seat Nut

If your Back Pressure Regulator is leaking through downstream, someone may have overtightened the seat during a repair.

Make sure the nut is tightened down, but not causing the seat to bulge. If the seat is bulging, back off the nut a quarter turn at a time until the seat sits flat.

What’s Considered a High Pressure Back Pressure Regulator?

Our original Back Pressure Regulator is the industry standard for holding back pressure of 300 PSI or less. However, if you need to hold back pressure above 300 PSI, you can use our High Pressure Control Valve in this application as well.

This valve can be used in conjunction with a pressure pilot to provide control in pressures up to 4,000 PSI.

Other Resources

For more information on the Kimray Back Pressure Regulator, check out these videos: