The glycol pump is the heart of any gas dehydration system. When producers run into challenges with the pump, it's often due to damage that occurred when the pump was started.

In this video, we show you how to start a glycol pump to prevent premature wear.

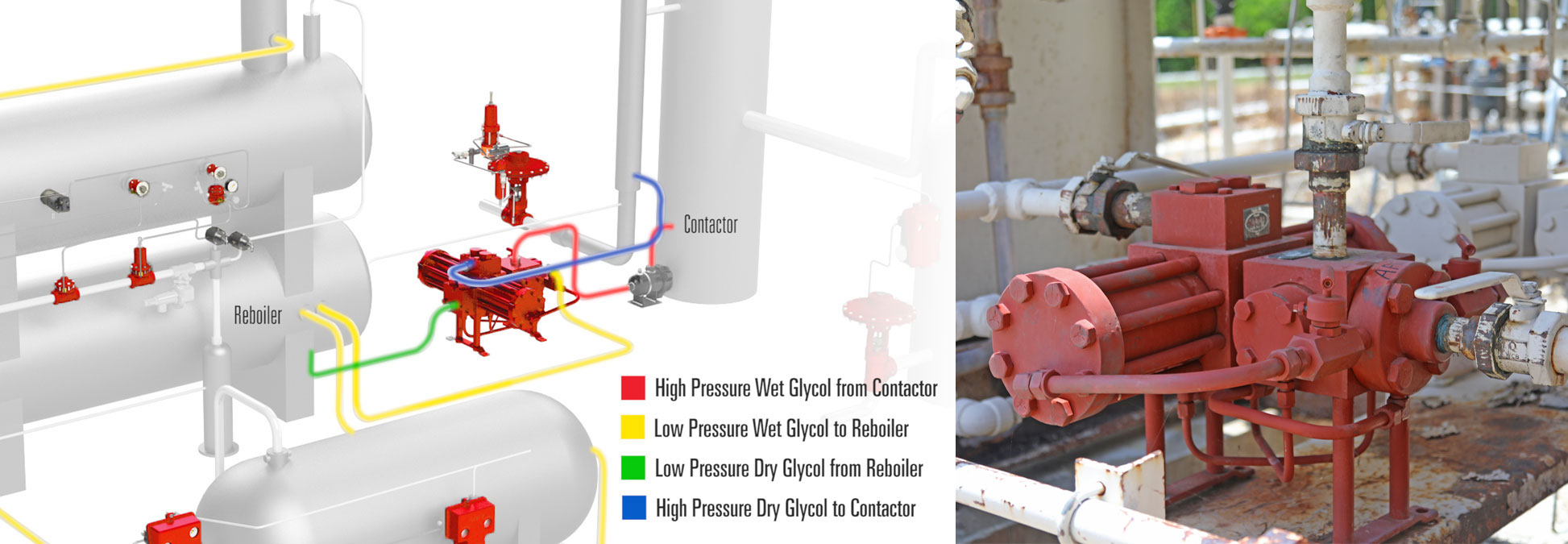

For this video, we used a testing station meant to simulate a field set up.

How to Start a Glycol Pump

1. Check for Debris

Always check for debris when starting. Any amount that gets into the pump can cause scoring on the cylinders or damage to the O-rings, which will then cause dry stroking.

If there is a completely clogged filter, glycol will not be present in the suction side of the pump, so the line coming into the pump is not liquid filled and dry stroking will occur.

2. Open Dehydration System Valves

If one of the valves is closed this could cause dry stroking, because glycol will not be present in the suction side of the pump.

3. Slowly Open the Main Gas Valve

A good rule of thumb is 5 seconds to fully open. A common mistake made in opening the valves is when the high pressure suction side of the pump from the contact tower is opened too quickly.

The pump needs a slow, gradual increase of pressure. The gas valve needs to be opened slowly so the pump isn’t being hit with all the incoming pressure at once.

4. Open the Needle Valves Evenly

You’ll begin by opening the needle valves counterclockwise. Starting from the fully closed position, they are often not parallel, so when they are open, they may be pointing different directions.

There may be a different number of turns required depending on the size and specifics of your pump. The main thing you want to listen for is when the pump is stroking evenly. This could happen anywhere between a small crack to three full turns.

You can do these one at a time, but make sure to open them evenly. When the inlet needle valves are not evenly opened, this causes short stroking. If the pump short strokes—meaning it is not pumping at full capacity, but only going halfway before going the other direction—you aren’t getting full flow rate. This wears out the cylinders faster because it’s only using part of them. The pump is having to work harder to circulate the right amount of glycol through the system.

You should hear the pump stroking back and forth at this point.

3 bonus tips for operating a glycol pump

Now that your pump is up and running, here are some bonus best practices to increase its longevity:

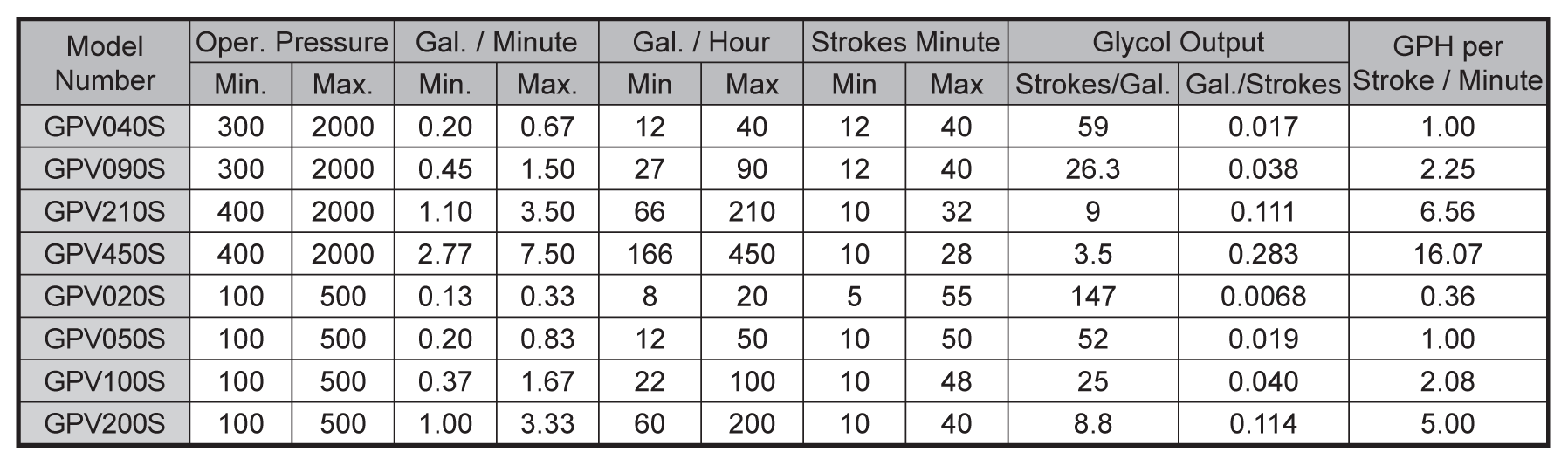

- Keep within the operating parameters of pump. The glycol temperature at the pump should be between 150-200 degrees Fahrenheit. The pressure ranges will differ based on your pump size.

- Make sure your filters are replaced regularly. There are a lot of O-rings in the glycol pump that can get sheared from debris if your filtration maintenance is not up to date. Watch our video about Glycol Filtration.

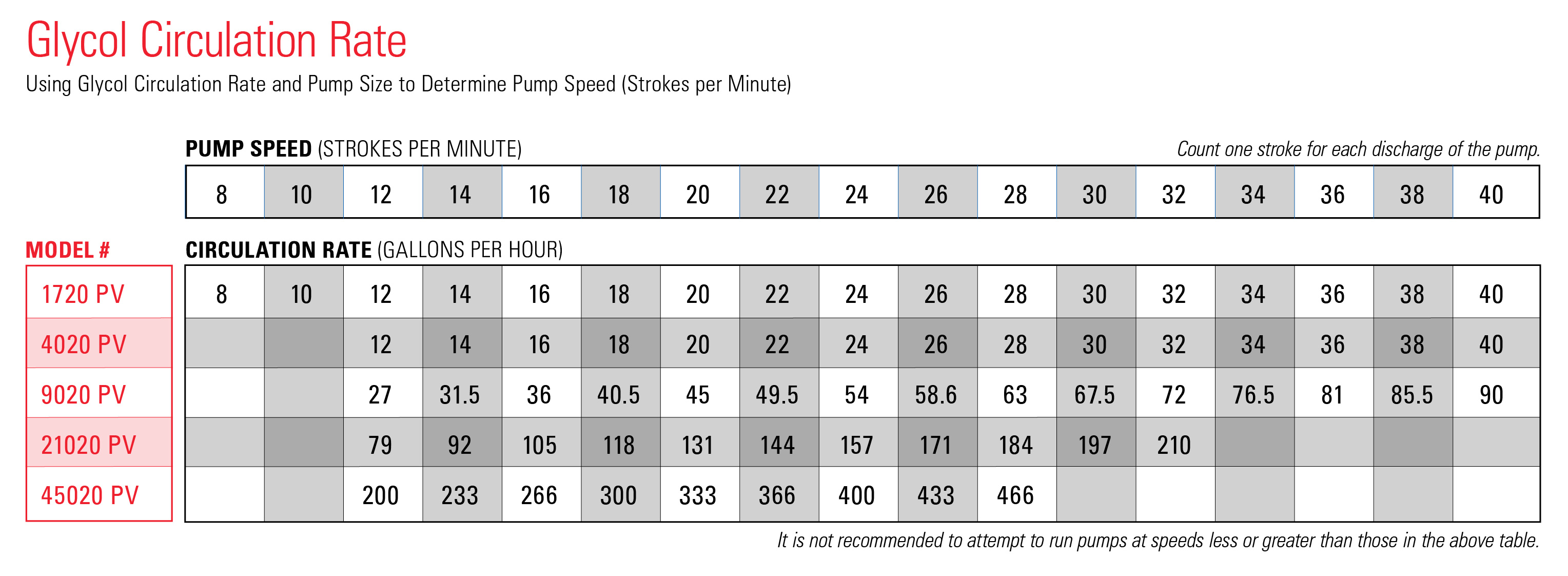

- Finally, make sure your glycol circulation rates are correct. Reference our video, “How to Determine your Glycol Circulation Rate.”

Happy dehydrating! Be sure to check out our Gas Dehydration playlist on Youtube for more helpful tips on how to make the best use of your Kimray glycol pump.