What is Control Valve Trim?

High Pressure Control Valve trim consists of three basic items: the stem, ball, and seat.

These are the operative parts that control the flow of liquid and gas through a valve. They are also the parts most exposed to process elements, and therefore most vulnerable to wear over time.

What Types of Valve Trim Are There?

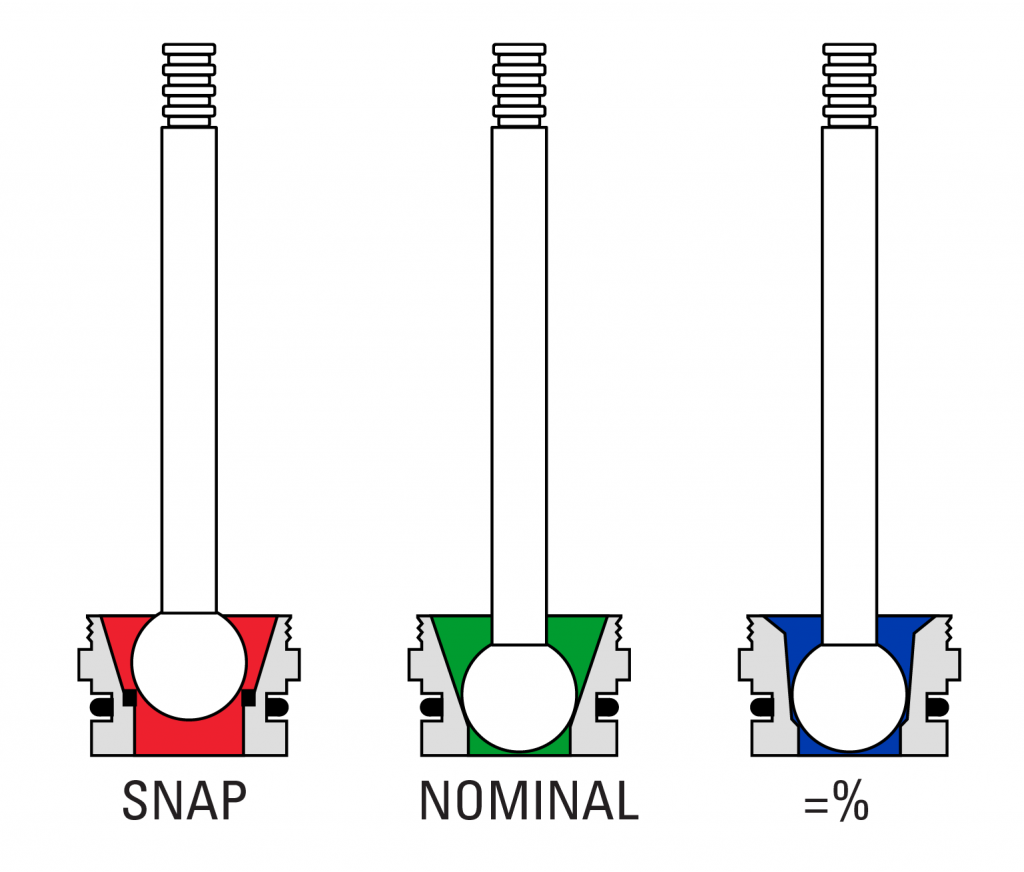

There are three primary types of control valve trim:

- Snap Trim (also referred to as Quick-Opening trim)

- Nominal Trim (also referred to as Linear trim)

- Equal Percentage Trim

Below, we'll outline the specific operation and typical applications for each control valve type.

What is a Valve's Flow Characteristic?

A valve trim’s flow characteristic is the relationship between the percentage of flow and the percentage of valve stem travel between 0% and 100%.

1. Snap Valve Trim

Snap Valve Trim opens quickly and is used for on/off service.

Primary applications include liquid dump, pressure relief, and metering. We also offer zirconia seats for erosive applications.

2. Nominal Valve Trim

Nominal valve trim is used for throttling liquids, liquid level control, and in applications where water hammering has been an issue.

3. Equal Percentage Valve Trim

Equal percentage valve trim is used to control pressure or flow of gases and vapors in throttling applications.

Valve trim for abrasive conditions

In oil and gas applications with highly abrasive conditions, control valves take a real beating.

Sand, salt, and other abrasive elements wear away the internal trim, packing, and body as it moves through the valve. Sources of valve abrasion include flowback, natural sand in the formation, and saltwater.

Wear and abrasion resistance is critical to optimal performance of oil and gas control valves. The premature wear abrasion causes to standard trim in control valves can cost you thousands in repairs and replacement valves, not to mention downtime. Therefore, choosing the right type of valve trim for your environment is key.

Kimray offers two High Pressure Control Valve trim materials designed to perform well in erosive conditions. These materials are harder than our standard trim and don’t wash out as fast.

Carbide Valve Trim

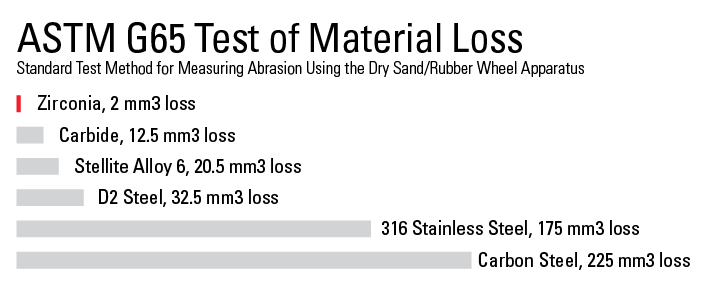

Carbide is a hard metal we recommend using for valve trim during flowback. In an ASTM G65 test of material loss, Carbide trim performed 2.5x better than standard D2 Steel trim.

Zirconia Valve Trim

Kimray’s wear-resistant Zirconia Trim is designed specifically for highly abrasive oil and gas applications. Zirconia offers a combination of abrasion and corrosion resistance not found in steels, alloys, or many forms of other ceramics and carbides.

Stellite vs. tungsten carbide vs. zirconia

Zirconia is a robust, hard ceramic material. It outperforms metal trim materials in abrasion resistance. This is an ideal solution for high-sand areas like North Texas, Australia, India, and China.

Zirconia is superior to Stellite and other metals for two reasons:

- It is a harder material than metal

- Because it is a ceramic and not metal, it is inert to corrosive material

Valve Trim Material Chart

In an ASTM G65 Sand Abrasion Test of material loss, Zirconia outperformed 316 Stainless Steel and Stellite.

The chart above shows the results of this test. It measures material loss based in cubic millimeters (mm3).

Kimray’s Magnesia Stabilized Zirconia valve trim performed 10 times better than Stellite Alloy and nearly 90 times better than 316 Stainless Steel. Kimray Tungsten Carbide also performed better than other metals.

Do You Operate Under Extreme Conditions?

Valve trim performance can be affected by more than just valve abrasion. Extremely high temperatures compromise metals like Stellite. Zirconia Trim is an ideal solution for operation in extreme temperatures.

This trim is designed to perform at temperatures ranging from -200°C to 850°C. Stellite, meanwhile, is only tested for temperatures between 315°C– 600°C. And because Zirconia is not a metal, it’s not subject to NACE.

Zirconia Applications

- Erosive/Abrasive Conditions

- Fracking

- Coal Seam Gas

Valve Trim Choices Are Easy with Zirconia

Kimray’s Zirconia Trim combats valve abrasion more effectively than any choice on the market. That keeps your valves up and running, and your well site reaching its peak performance.

Zirconia Trim is available now in Kimray High Pressure Control Valves. For more information on Zirconia Trim, you can download our brochure.

THE WRONG VALVE TRIM: A use case

Recently a producer in the Woodford Shale contacted us with a problem.

They had been using Kimray High Pressure Control Valves for years, but had begun to burn through a lot of trim sets in the valves, replacing them more often than expected. We began asking questions.

Q: What have you been ordering?

A: High Pressure Control Valve packages for all new construction

Q: What type of trim are you requesting on these valves?

A: 5/8" equal percentage trim

Q: What are the temperatures and flow rates of your wells?

A: Conditions differ depending on the well

This was a problem we were prepared for.

Conditions are rarely the same well to well in the various locations and applications where Kimray customers operate. Because of this, we offer different types of valve trim designed to handle different temperatures, pressures, flow rates, and process fluids.

In this case, the equal percentage trim this customer was using was designed primarily for gas applications, where precise throttling is ideal.

Their new wells, however, were flowing liquid, and bringing a lot of sand to the surface along with it. Because they were using equal percentage trim, the valve was consistently open, subjecting the trim to the abrasive, sandy flow path. This was the central reason for the premature wear.

We advised the customer that carbide snap trim for these valves would be a better option. This would give them a harder ball and seat, and the snap trim opens and closes quickly, so it would be exposed to the abrasive flow less often and therefore last longer.

We also helped the customer resize their valves accordingly to the appropriate flow rates of the wells. Because our trim can be field converted, they didn’t have to order new valves, just outfit their existing ones with the new, better suited trim.

Step-By-Step Guide to replace Valve Trim

Need to update the trim in your existing valves to handle changing conditions? Follow our step-by-step video on replacing valve trim.

To speak with an expert about finding the trim set that best fit your flow conditions, contact your local Kimray store or authorized distributor.