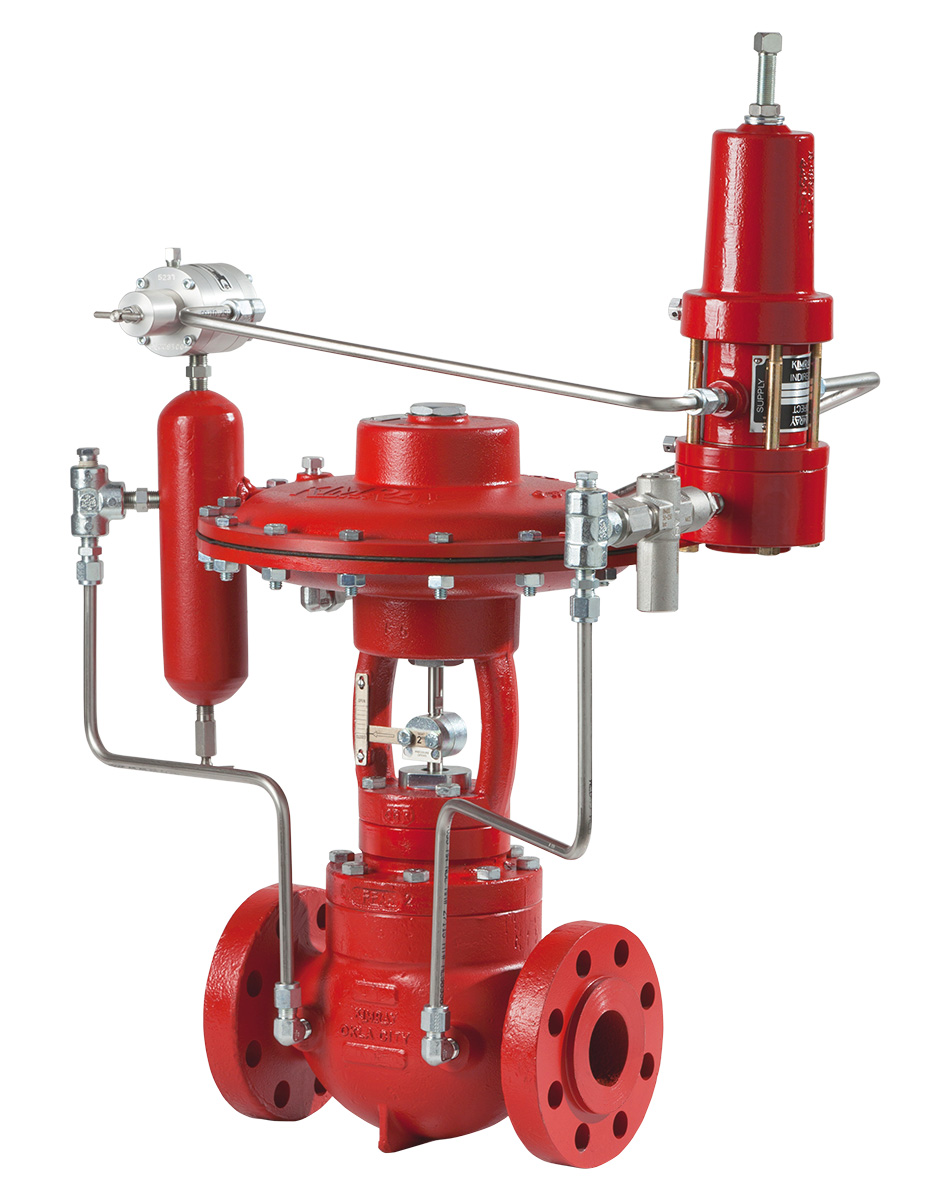

When building a regulator package with a Kimray High Pressure Control Valve and Control Valve Pilot, the standard configuration calls for the following:

- Back Pressure control: a fail-open valve

- Pressure Reducing control: a fail-closed valve

This is based on the assumption that a back pressure regulator protects the upstream from over pressure and therefore should “fail open,” and that a pressure reducing regulator protects the downstream from over pressure and therefore should “fail closed.”

When is an Indirect Pilot Used?

Of course, the desired set point will dictate the pressure range of the pilot. But for typical applications, the action of the pilot will always be indirect.

Back Pressure: A back pressure regulator needs to open when the upstream pressure is above the set point. So with a fail-open valve, the pilot out put would need to drop on sensed high pressure.

Pressure Reducing: A pressure reducing regulator needs to close when the downstream pressure is above the set point. So with a fail-closed valve, the pilot output would need to drop on sensed high pressure.

In both cases, an indirect control valve pilot fits the need.

When is a Direct Pilot Used?

A direct pilot is needed if you are going to deviate from the standard set up based on unique circumstances. For example, if you have a fail-closed back pressure valve or a fail-open pressure reducing valve.

*Note: If you want to convert your valve from Back Pressure to Pressure Reducing, you’ll want to convert the topworks, not the pilot action.